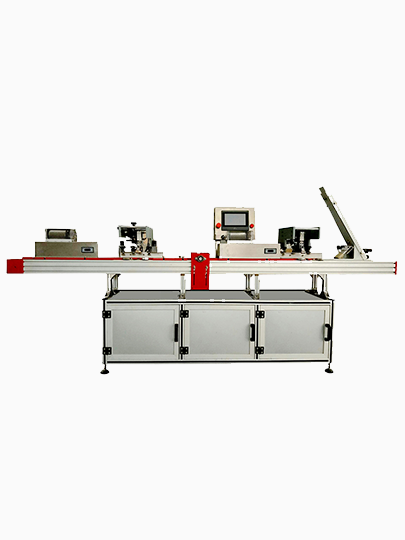

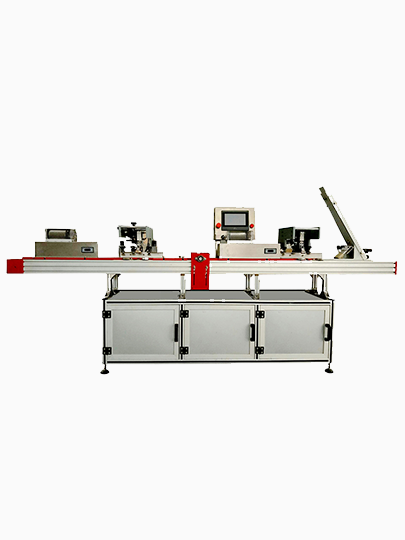

Labeling machine is a kind of equipment that specifies self-adhesive label or foil label on packaging container. Labeling machine is an indispensable part of modern packaging. At present, the types of labeling machines in China are gradually increasing, and the technical level has also been greatly improved. From the backwardness of manual and semi-automatic labeling to the mode of full-automatic high-speed labeling machine occupying a broad market.

Main structural components of automatic labeling machine:

1. Peel off the board. When the back paper changes direction through the stripping board, there is an angle with one end of the stripping board (generally less than 30 °), so that the label is easy to mark and separate from the back paper, so as to realize contact with the label. Label object.

2. Guide roller. It is composed of upper and lower parts, which plays the role of guiding and positioning drum materials.

3. Buffer wheel. The work is attached to a spring that swings back and forth. The purpose is to absorb the tension of the roller material when the equipment is started, make the material contact with each roller and prevent the material from breaking.

4. Drive the drum. It is composed of a group of driving friction wheels. One is usually a rubber roller and the other is a metal roller through which the backing paper passes. Its function is to drive the roller materials to achieve normal marking.

5. Roller. As a driving wheel with friction transmission device, its function is to rewind the labeled backing paper. The rotation of the paper wheel does not interfere with the processing paper of the driving wheel, and the synchronous transmission is adjusted by the friction device.

6. Mark the roller. The label shall be evenly and evenly pasted on the object to be pasted from the lining.

7. Roller. The driven wheel used to place the roller label. It is usually equipped with friction braking device to control the speed and tension of the drum to keep the paper conveying smooth.

This is the main part of the labeling machine. Wheel, plate and Kun form a full-automatic labeling machine, which can help you label without being on duty, saving time and effort.

Nowadays, Social labeling machine has become an indispensable part of production enterprises. After continuous development, it has become a real commodity. At the same time, people's demand for self-adhesive labeling equipment is also increasingly diversified, which is both a challenge and an opportunity for the labeling machine industry. Therefore, as the main productivity of labeling machine, China's labeling industry is moving towards integration.

With the development of economy, China's packaging machinery industry continues to develop. Labeling equipment has successfully changed its subordinate position and become a real commodity. The sales volume of equipment in developing countries will exceed that in the United States in the next few years. At present, China has become the world's most potential packaging machinery market, and many foreign packaging enterprises have begun to enter the Chinese market, which puts forward higher requirements for domestic packaging enterprises. China's packaging machinery industry has great development potential. Whether we can seize these opportunities is very important for the future development of packaging manufacturers.

Automatic labeling machine is widely used in various fields. Many manufacturers choose modern labeling machines to label their products. However, many manufacturers are not familiar with the machine and learn how to operate it, but ignore its daily maintenance. The automatic labeling machine is easy to inhale dust during operation, so the dust on the labeling machine must be cleaned regularly.

When the labeling machine is temporarily idle, unplug the power supply and cover it with dust-proof cloth to prevent dust from falling on the labeling machine. In addition, the hot area of the labeling machine should be cleaned regularly to ensure the high-quality operation of the labeling machine. Secondly, the automatic labeling machine should not forget to apply some lubricating oil for maintenance.

After the labeling machine runs for a long time, it should be lubricated to a certain extent. Many mechanical parts, such as gears, bearings and gearboxes, are easy to rust and wear after use for a period of time. And apply lubricating oil to ensure the smooth operation of the labeling machine. It must be pointed out that the labeling machine should be lubricated after 48 hours of continuous operation.